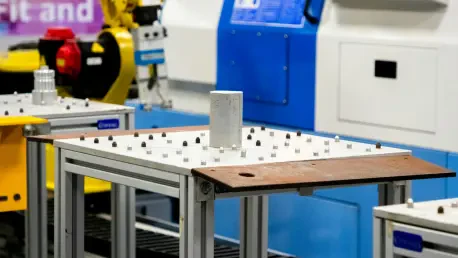

Imagine a bustling factory floor where production halts not because of machine failure, but due to a shortage of skilled engineers needed to design essential tooling like fixtures and jigs, a scenario that costs manufacturers valuable time and resources every day. This persistent challenge of labor scarcity and workflow bottlenecks has long plagued the manufacturing sector, slowing down operations and stifling agility. However, a new wave of additive manufacturing (AM) software is stepping in to transform this landscape, empowering factory floor operators to take on tasks once reserved for specialized engineering teams. By integrating advanced, user-friendly tools, these solutions are streamlining processes and redefining efficiency at the ground level. This shift promises not only to address immediate pain points but also to reshape how factories operate, making production more adaptable and scalable in an industry hungry for innovation.

Breaking Down Barriers in Tooling Design

Empowering Operators with Simplified Solutions

The traditional model of tooling design has often been a time-intensive process, heavily reliant on engineers with advanced CAD skills to create fixtures and other critical components, sometimes taking a full day or more to complete a single task. This dependency creates significant delays, especially in environments where skilled labor is scarce, leaving production lines idle and manufacturers scrambling for solutions. Enter the latest advancements in AM software, which are designed to shift this responsibility directly into the hands of AM operators. These tools feature intuitive interfaces that drastically cut down design time, with early adopters reporting up to an 80% reduction, often completing professional-grade fixtures in under 20 minutes. By eliminating the need for specialized expertise, this approach not only accelerates workflows but also frees up engineering talent to focus on more complex, value-added projects, ultimately boosting overall productivity on the factory floor.

Reducing Bottlenecks for Greater Agility

Beyond just simplifying the design process, these software innovations tackle the broader issue of operational bottlenecks that plague manufacturing facilities. When tooling design is confined to a small group of skilled engineers, any delay in their availability ripples through the production schedule, hampering output and increasing costs. Modern AM platforms address this by democratizing access to design capabilities, allowing operators to create necessary tools right at the point of need without waiting for upstream resources. This newfound autonomy enhances the speed of response to production demands, enabling factories to adapt quickly to changing requirements or unexpected challenges. Moreover, by reducing reliance on a limited pool of experts, companies can better navigate labor shortages, ensuring that even in times of staffing constraints, the factory floor remains active and efficient, ready to meet market demands with minimal disruption.

Enhancing Workflow Efficiency Through Integration

Streamlining Operations with Unified Platforms

One of the standout features of cutting-edge AM software is its ability to consolidate disparate workflows into a single, cohesive platform, a development that significantly enhances operational efficiency. Historically, manufacturers have juggled multiple software licenses and systems to manage different AM technologies, leading to fragmented processes and wasted time. The latest solutions integrate support for a wide range of technologies—such as FDM®, PolyJet™, SAF™, P3™, and stereolithography—along with compatibility for third-party systems like powder bed fusion and SLA. This unification eliminates the need for constant switching between tools, providing operators with a seamless environment to manage print jobs, apply 3D textures for better grip and aesthetics, and reduce support material usage. The result is a streamlined operation where tasks that once took hours across various platforms are now completed swiftly within one interface, saving both time and resources.

Optimizing Multi-Tasking and Post-Processing

Another critical advantage of these advanced software tools lies in their capacity to handle complex, multi-session print jobs while simplifying post-processing, two aspects that are vital for maintaining a smooth factory floor rhythm. Operators can now oversee several print tasks simultaneously without losing track of progress or quality, a feature that maximizes machine uptime and throughput. Additionally, new functionalities aimed at minimizing support structures mean less material waste and faster cleanup after printing, reducing manual labor in post-processing stages. These improvements collectively contribute to a more efficient production cycle, where downtime is minimized, and output is maximized. For manufacturers, this translates into tangible cost savings and the ability to scale operations more effectively, as operators gain the flexibility to manage larger workloads with fewer interruptions, ensuring that production goals are met consistently and on schedule.

Paving the Way for Scalable Manufacturing

Addressing Industry-Wide Challenges

Reflecting on the strides made by AM software, it’s evident that the industry has taken significant steps to confront longstanding challenges like labor shortages and workflow inefficiencies. The introduction of platforms that empower operators to handle tooling design directly at the factory floor marked a turning point, alleviating the pressure on engineering teams and accelerating production timelines. These tools have proven instrumental in bridging the gap between technical expertise and operational needs, ensuring that even in the face of staffing constraints, manufacturing processes remain robust and responsive. By focusing on accessibility and speed, the software addresses critical pain points, setting a new standard for how factories can operate under pressure while maintaining high productivity levels.

Looking Ahead to Future Innovations

As the manufacturing sector continues to evolve, the legacy of these software advancements offers a clear path forward for further innovation. Companies should prioritize integrating such user-centric tools into their operations, focusing on training programs that equip operators with the skills to leverage these platforms fully. Additionally, exploring partnerships with software developers can help tailor solutions to specific factory needs, enhancing adaptability. Looking to the horizon, the emphasis must remain on scalability—ensuring that as demand grows, systems are in place to support increased output without sacrificing efficiency. By building on the foundation laid by these transformative tools, the industry can anticipate a future where technology and human capability work hand in hand to overcome any obstacle, driving manufacturing into a new era of flexibility and success.