The intricate web of global commerce, once a celebrated model of efficiency and interconnectedness, is now showing profound signs of strain under the relentless pressure of continuous, overlapping crises. From lingering pandemic aftershocks and severe climate-related disruptions to escalating geopolitical risks and rapidly shifting consumer demands, the systems that move goods around the world are facing what many industry leaders call an “age of uncertainty.” In this volatile new reality, the traditional, fragmented approaches to supply chain management have proven dangerously inadequate. The old rules, built on predictability and siloed operations, are breaking down. This has created an urgent imperative for a new operating model, one that can deliver unprecedented speed, precision, and resilience. Emerging from this crucible of challenges, artificial intelligence is no longer just a tool for marginal gains but a transformative force capable of fundamentally redesigning the very foundation of how businesses manage the flow of materials, products, and information.

Navigating a Perfect Storm of Disruption

The modern supply chain is being battered by a convergence of powerful and destabilizing forces that expose deep-seated vulnerabilities across the global network. On one side, the system is reeling from a series of acute supply shocks. Climate events, such as the severe drought impacting the Panama Canal’s operational capacity, create logistical bottlenecks that ripple through international trade, while simmering regional conflicts threaten established shipping routes and longstanding partnerships. These external pressures are compounded by challenges from within the market itself. The widespread adoption of e-commerce has not only fragmented delivery networks but also drastically heightened consumer expectations for speed and convenience. Simultaneously, a diversification of lifestyles has fueled a growing appetite for personalized and customized products, rendering traditional mass-market forecasting models increasingly obsolete. This multifaceted crisis demands an operational agility that legacy systems simply cannot provide, making the need for a paradigm shift more critical than ever.

This environment of constant disruption has laid bare the critical flaw of traditional supply chain management: its reliance on disconnected, siloed systems. Even within a single enterprise, functions like sales, production, logistics, and warehousing frequently operate on disparate software platforms, creating information black holes that prevent a holistic view of the entire operation. This fragmentation leads to significant delays, costly inefficiencies, and reactive, often flawed, decision-making. The problem is magnified exponentially when extended across the external network of suppliers, carriers, and customers, where a lack of real-time visibility and communication creates friction at every handoff. In the face of today’s volatility, this fragmented model is no longer viable. The new competitive imperative is to build a supply chain that operates with exceptional speed and precision, enabling the agility required to anticipate, absorb, and respond to shocks and fluctuations with intelligence and confidence.

The Dawn of an Integrated AI Ecosystem

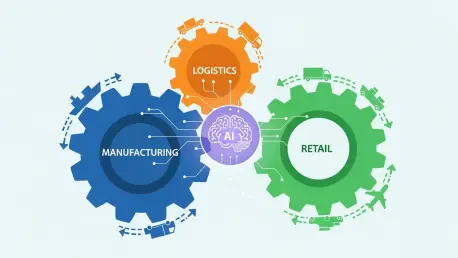

The answer to this crisis of fragmentation is emerging in the form of AI-powered solutions designed to create a single, unified ecosystem where all partners can collaborate seamlessly. This new paradigm is built upon a cloud-native architecture and a centralized AI data cloud, which serve as the technological backbone for end-to-end connectivity. This model connects manufacturers, wholesalers, retailers, and transporters onto a common, real-time platform, effectively dismantling the information silos that have plagued the industry for decades. By orchestrating the entire supply chain from a single control tower, companies can eliminate the communication gaps and time lags inherent in traditional systems. The tangible benefit of this integrated approach is a radical reduction in response time to disruptions. What previously took days or even weeks of manual analysis and coordination across different teams and organizations can now be resolved in a matter of minutes, enabling a level of operational agility that was previously unimaginable.

At the technological heart of this transformation is a proprietary AI model engineered to replicate and significantly enhance human decision-making processes. This advanced system operates on a continuous cycle known as the SADA Loop: it can See and visualize vast amounts of complex information, Analyze the data to identify critical patterns and insights, Decide on the optimal course of action, and then Act to execute that decision in the physical world. This creates a powerful closed-loop system of continuous, real-time optimization. Unlike earlier analytical tools that merely presented data for human interpretation, this AI can translate digital insights into tangible, real-world actions, such as rerouting shipments or adjusting production schedules. This unique capability dramatically enhances the precision of responses to supply chain uncertainties, moving businesses from a reactive posture to a predictive and proactive one, where potential problems are identified and mitigated before they can escalate into major crises.

A New Paradigm for Humans and Machines

Recognizing that a complete technological overhaul can be a daunting prospect for large enterprises, the most effective path forward involves a pragmatic and incremental implementation strategy. Rather than initiating a massive, all-encompassing transformation project from the outset, the recommended approach is to “start small.” This philosophy encourages companies to begin by identifying and solving one specific, high-impact problem, such as optimizing inventory levels for a key product line or improving the efficiency of a single warehouse. Achieving a quick win in a focused area allows the organization to demonstrate clear value and build internal momentum, all while operating under a broader strategic vision to eventually migrate all processes onto the common, unified platform. This approach also reinforces a critical understanding: that supply chain management is fundamentally a data problem. The proliferation of disconnected applications within most companies underscores the fact that a unified data platform is the essential prerequisite for any successful and scalable AI implementation.

A significant trend shaping this transformation is the deployment of specialized AI agents that leverage the sophisticated language comprehension and generation capabilities of generative AI. These agents are designed to autonomously handle complex operational tasks such as planning, decision-making, and execution to achieve specific objectives. Instead of a single monolithic AI, this model incorporates a suite of these agents, each dedicated to autonomously managing a specific domain like inventory, shelf space, warehouses, logistics, or overall network flow. Contrary to the lazy analogy that these agents will simply replace human workers, they are better framed as powerful tools for human augmentation. They can be delegated the mundane, repetitive, and low-value tasks that consume a significant portion of a skilled worker’s time. This frees human employees to focus on higher-level strategic objectives, including complex problem-solving, fostering deeper collaboration with colleagues and suppliers, and driving innovation. The ultimate outcome is a significant boost in productivity and, ideally, a more engaged and satisfied workforce.

Forging the Supply Chain of Tomorrow

The path forward was ultimately defined by a vision centered on powerful strategic synergies. The strategy involved fusing cutting-edge AI software with deep expertise in the physical world, leveraging technologies like advanced sensing and edge devices to create unique, highly competitive solutions that seamlessly bridged the digital and physical realms. This direction was underpinned by a substantial commitment, with approximately $2 billion invested over the past three years toward product innovation and strategic acquisitions. Furthermore, the construction of a more robust, cross-industry supply chain ecosystem was accelerated through powerful alliances, including a development partnership with the data cloud platform Snowflake and a strengthened collaboration with Microsoft to co-develop new AI-powered solutions. The overarching goal that emerged from these efforts was a commitment to creating a future where the most advanced AI is accessible and applicable on the frontlines, making the global supply chain more resilient, efficient, and responsive to the needs of the world.