The very materials designed to heal the human body and push the boundaries of aerospace engineering have long presented a profound manufacturing paradox, being so resilient that shaping them into intricate components was once a battle of brute force against immense cost. This long-standing challenge is now being addressed not by a stronger tool, but by a smarter one, as researchers have successfully integrated artificial intelligence with advanced micromachining to unlock the full potential of next-generation biocompatible alloys. This breakthrough signifies a pivotal shift toward intelligent manufacturing, holding the potential to make safer, more durable medical implants and high-performance aerospace parts more accessible and reliable than ever before.

Engineering Safer and Stronger Medical Implants

For decades, the medical industry has relied heavily on titanium alloys for implants like hip replacements and dental fixtures, prized for their strength, light weight, and corrosion resistance. However, the most common of these, Ti–6Al–4V, contains aluminum and vanadium, elements that have raised concerns about potential long-term toxicity as they can leach into the body over time. This biocompatibility dilemma has driven a quest for safer alternatives that offer the same, if not better, performance without the associated risks.

In response, materials scientists have developed a new class of alloys that are free of potentially harmful elements. One of the most promising is Ti–29Nb–13Ta–4.6Zr (TNTZ), a material composed entirely of biocompatible elements like niobium, tantalum, and zirconium. This alloy not only eliminates toxicity concerns but also exhibits superior mechanical properties, making it an ideal candidate for long-lasting medical implants and demanding aerospace applications. The primary barrier to its widespread adoption, however, has been a significant manufacturing bottleneck: its extreme hardness makes it nearly impossible to shape with conventional cutting and grinding methods.

The Challenge of Shaping Advanced Materials

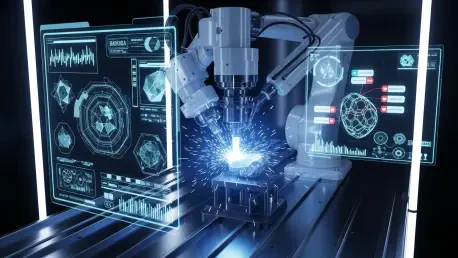

To overcome the manufacturing hurdles posed by materials like TNTZ, engineers have turned to non-traditional methods. One such technique, micro-electro-discharge machining (µ-EDM), is exceptionally well-suited for the task. Instead of physical cutting, µ-EDM uses a series of precisely controlled electrical sparks to erode material from a workpiece, allowing it to shape even the hardest conductive materials with incredible precision. This process is perfect for creating the complex micro-features required for advanced medical devices.

Despite its advantages, µ-EDM is an inherently complex process governed by dynamic thermal and electrical interactions that are difficult to predict and control. Achieving the desired balance of machining speed, dimensional accuracy, and surface quality often involves extensive and costly trial-and-error experimentation. This unpredictability has hindered the efficient and scalable production of components from advanced alloys, creating a need for a more intelligent and data-driven approach to manufacturing.

Fusing Micromachining with Machine Learning

To tame the complexity of µ-EDM, a research team developed an innovative framework that combines physical experimentation with the predictive power of machine learning. They systematically machined the TNTZ alloy using tungsten-carbide electrodes, carefully varying key electrical parameters—namely voltage and capacitance—which control the energy of each spark. Throughout this process, they meticulously measured critical performance metrics, including the material removal rate, the dimensional accuracy and circularity of the micro-holes created, and the final surface roughness.

The core of their strategy was to leverage this experimental data to train and test multiple machine learning models. The goal was to find an algorithm capable of accurately forecasting the machining outcomes based solely on the input parameters. Three distinct models were evaluated: a standard multiple linear regression model, a decision-tree algorithm, and a more sophisticated artificial neural network (ANN). By creating a reliable predictive tool, the team aimed to replace the inefficient trial-and-error approach with a streamlined, data-driven optimization process.

Decoding the Intricacies of Micromachining

The results of the study provided clear and actionable insights into the µ-EDM process. The analysis revealed that capacitance was the single most dominant factor, influencing nearly 90% of the variation in the machining outcomes. This parameter dictates the amount of energy stored and released in each spark, directly impacting both the speed and the quality of the work. A fundamental trade-off emerged: higher discharge energy, driven by increased capacitance, significantly accelerated the material removal rate but simultaneously degraded the surface finish and geometric precision of the machined part.

When the predictive capabilities of the AI models were compared, the artificial neural network proved to be the standout performer. It far surpassed the other models, demonstrating a remarkable ability to understand the complex, nonlinear relationships within the µ-EDM process. The ANN achieved a prediction accuracy with a coefficient of determination (R²) near 0.99 and error rates below 5%, confirming its potential as a powerful tool for process optimization. Microscopic analysis of the machined surfaces corroborated these findings, showing that higher energy discharges created larger surface craters and even caused material from the tool electrode to transfer to the alloy, a critical consideration for high-purity applications like medical implants.

A Blueprint for Intelligent Manufacturing

This successful fusion of AI and advanced machining provides a powerful blueprint for the future of manufacturing. With a validated ANN model, engineers can now move beyond prediction and toward true optimization, selecting the ideal µ-EDM parameters to achieve a specific, desired balance between production speed and component quality before a single spark is ever fired. This capability is poised to make the widespread industrial adoption of safer, high-performance biocompatible alloys more economically viable, accelerating their use in critical applications.

The practical insights gained from this research are invaluable. Understanding the direct relationship between electrical energy input and the resulting surface integrity is crucial for manufacturing components where purity and precision are non-negotiable. This work did more than just solve a specific manufacturing problem; it demonstrated a scalable methodology for integrating intelligence into complex industrial processes. The path forward involves expanding these AI models with more data and additional parameters, creating an even more robust and versatile tool that could redefine how next-generation materials are brought from the laboratory to the real world.