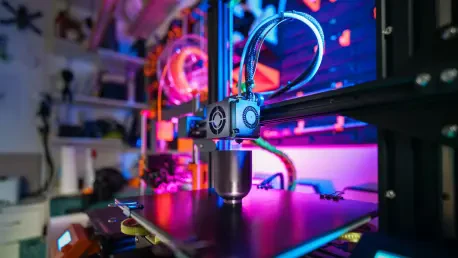

I’m thrilled to sit down with Laurent Giraid, a technologist whose groundbreaking work in sustainable 3D printing is turning heads in the industry. With a deep-rooted passion for merging cutting-edge technology with environmental responsibility, Laurent has been a driving force behind innovative projects like SustainaPrint, a system that balances eco-friendliness with structural strength in 3D printing. Today, we’ll dive into the inspiration behind this project, explore how it works, and discuss its potential to reshape manufacturing with sustainability at its core.

How did the idea for SustainaPrint come about, and what sparked your passion for tackling sustainability in 3D printing?

Honestly, it started with a frustration I think many in the field share. 3D printing is incredible for rapid prototyping and custom manufacturing, but the reliance on petroleum-based plastics always felt like a huge missed opportunity. I wanted to address the environmental impact without sacrificing the functionality of printed objects. The idea for SustainaPrint emerged from conversations with colleagues about how we could strategically use materials—focusing stronger plastics only where needed and opting for greener alternatives everywhere else. It’s about finding that sweet spot between performance and planet-friendly design.

What specific challenges in the 3D printing world were you aiming to solve with SustainaPrint?

One of the biggest hurdles is the trade-off with eco-friendly filaments. They’re often biodegradable or recycled, which is great for sustainability, but they tend to be brittle under stress. That makes them impractical for anything load-bearing or structural. We wanted to create a system that could analyze an object’s design, pinpoint where strength is critical, and reinforce just those areas while keeping the rest green. It’s a way to cut down on high-performance plastic use without compromising on durability.

Can you walk us through how SustainaPrint actually works when someone uses it to design and print an object?

Sure, it’s a pretty intuitive process. A user starts by uploading their 3D model into our custom interface. They define where forces will be applied and which parts are fixed—like where a hook might be mounted to a wall. Then, the software runs a simulation called Finite Element Analysis to map out stress distribution across the object. It identifies high-stress zones that need reinforcement with tougher material and leaves the rest for eco-friendly filament. From there, it generates a printing plan for a dual-extrusion printer to layer both materials strategically. It’s all about precision and efficiency.

How does the software determine exactly where stronger material is needed in an object?

The magic happens in the stress simulation. Using Finite Element Analysis, the software breaks down the object into tiny virtual elements and predicts how each part will react under specified forces—whether it’s tension, compression, or bending. It creates a detailed map of pressure points, highlighting areas most likely to fail. Based on that, it applies rules to decide which sections need the tougher filament. It’s not just guesswork; it’s driven by solid engineering principles to ensure reliability.

Why did your team choose materials like PolyTerra PLA and Tough PLA for this project, and what makes them a good fit?

We picked PolyTerra PLA because it’s a fantastic eco-friendly option. It’s made with a focus on sustainability, often incorporating bio-based or recycled components, and it has a lower environmental footprint than traditional plastics. On the other hand, Tough PLA from brands we tested offers enhanced durability and impact resistance compared to standard PLA. It’s ideal for reinforcing critical areas without jumping to petroleum-heavy materials. Together, they let us balance green goals with the strength needed for functional prints.

During testing, you printed a range of objects. Can you share a standout example that surprised or impressed you?

One that really caught our attention was a dome-shaped structure. When we tested the hybrid version—part eco-friendly, part reinforced—it actually outperformed the one printed entirely in Tough PLA. We think it’s because the strategic mix of materials helped distribute stress more evenly, avoiding the kind of brittle failure you sometimes see with uniform stiffness. It was a powerful reminder that sometimes, less of a strong material, used smarter, can yield better results.

Sustainability is at the heart of SustainaPrint. How significant do you think its impact could be on reducing material waste in 3D printing?

I believe the impact could be substantial, especially as 3D printing scales up in industrial and distributed manufacturing. By using up to 80% eco-friendly filament in some designs, we’re drastically cutting down on high-performance plastics that are harder to recycle and more resource-intensive to produce. If adopted widely, this approach could reduce overall plastic consumption in the industry while still meeting performance needs. Plus, it encourages a mindset shift—sustainability doesn’t have to mean compromise; it can be part of smarter design.

Tell us about the DIY testing toolkit you developed. How does it help users, and who is it meant for?

The toolkit is something we’re really excited about. It’s a low-cost, 3D-printable device designed for hobbyists, educators, and small-scale makers who want to test filament strength before committing to a big print. It includes modules for checking tensile and flexural strength, and it pairs with everyday items like digital scales or pull-up bars to measure performance. It’s meant for anyone who doesn’t have access to fancy lab equipment but still wants reliable data on how their materials will hold up.

Looking ahead, what’s your forecast for the future of sustainable 3D printing technologies like SustainaPrint?

I’m optimistic that we’re on the cusp of a real transformation. As tools like SustainaPrint become more accessible—especially with plans to release it open-source—I think we’ll see a wave of adoption from classrooms to factories. I foresee advancements in software, like using AI to automate stress modeling based on an object’s shape alone, and broader material options as greener filaments get stronger. Ultimately, I believe sustainable 3D printing will become the norm, not the exception, as we integrate environmental considerations into every step of design and production.