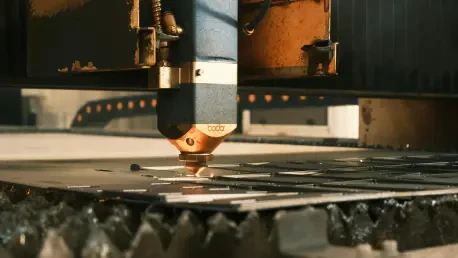

Imagine a world where precision manufacturing achieves near-perfect results with minimal trial and error, where defects in critical components for electric vehicles are virtually eliminated through intelligent automation. This vision is becoming a reality as artificial intelligence (AI) transforms laser welding, a cornerstone of industries like automotive and aerospace. Laser welding, essential for creating high-strength, lightweight structures such as fuel cells, often faces challenges like defects caused by high-speed processes. These imperfections can compromise safety and performance, posing persistent hurdles for manufacturers. This analysis explores how AI, particularly large language models (LLMs), is revolutionizing the field by addressing data scarcity and enhancing efficiency. It delves into current breakthroughs, gathers expert insights, and examines the future potential of this game-changing trend, offering key insights for industry stakeholders.

The Rise of AI in Laser Welding: A Game-Changing Trend

Overcoming Data Scarcity with Cutting-Edge Solutions

Laser welding research has long been hampered by the limitations of traditional methods, which often demand extensive datasets—sometimes exceeding 1,000 data points—to develop reliable predictive models. Such an approach requires significant time and resources, often involving exhaustive manual reviews of existing literature to extract relevant information. According to studies published in the International Journal of Machine Tools and Manufacture, deriving a single predictive equation using conventional techniques can take hours or even days of labor-intensive effort, stalling innovation in fast-paced industries.

AI is emerging as a powerful solution to these constraints, effectively bridging gaps in data availability and streamlining research processes. By leveraging advanced algorithms, manufacturers can now analyze smaller datasets alongside textual information from prior studies, drastically reducing the workload. This shift not only saves time but also enables broader application of predictive models across varying welding conditions, marking a significant departure from outdated practices.

The adoption of AI in this domain reflects a broader trend in manufacturing toward data-driven decision-making. As industries face increasing pressure to innovate rapidly, the ability to generate actionable insights with limited experimental data is becoming indispensable. This technological pivot is poised to redefine how research is conducted, pushing the boundaries of what is possible in precision engineering.

Real-World Applications and Transformative Breakthroughs

A standout example of AI’s impact comes from a research team at Penn State University, which has developed an AI-powered integration framework utilizing LLMs to derive predictive equations with minimal data. By combining just five experimental datasets with 43 extracted from existing literature, this framework offers a robust method to model complex welding phenomena. Its ability to process unstructured textual data into numerical insights sets it apart from traditional approaches, demonstrating practical utility in real-world scenarios.

One specific application of this framework addresses the notorious “humping” defect, a common issue in high-speed laser welding used for electric vehicle fuel cells. Humping, characterized by uneven weld beads due to excessive speed, can weaken structural integrity. The AI-driven equations provide detailed relationships between physical parameters like melt velocity and thermal conductivity, enabling researchers to predict and mitigate such defects with unprecedented accuracy, even under diverse conditions.

Efficiency is another hallmark of this innovation, with the framework generating 10 candidate equations in just one minute—a stark contrast to the hours required by conventional methods. This rapid output allows engineers to test multiple scenarios swiftly, accelerating the optimization of welding processes. Such advancements underscore AI’s transformative potential, offering tangible benefits to industries reliant on precision and speed.

Expert Perspectives on AI’s Role in Welding Innovation

The research team at Penn State, including Zhengxiao Yu, Zen-Hao Lai, and Jingjing Li, provides valuable insights into AI’s evolving role in manufacturing. Yu emphasizes the remarkable speed of the LLM framework, noting its ability to condense complex research tasks into mere minutes. Lai focuses on its targeted application, particularly in tackling specific defects like humping, which have long plagued high-speed welding processes. Their combined perspectives highlight how AI enhances operational efficiency while addressing critical quality concerns.

Li adds a nuanced viewpoint, stressing the importance of human expertise in the equation selection process. While the framework generates multiple options, domain knowledge remains essential for identifying the most accurate and applicable models. This balanced outlook positions AI as a collaborative tool rather than a standalone solution, ensuring that technological advancements complement rather than replace skilled professionals in the field.

The team’s optimism about scalability further reinforces the significance of this trend. They envision the framework’s adaptation to other industrial applications, reflecting a growing consensus among experts about AI’s potential to revolutionize manufacturing. Their insights suggest that as AI tools become more refined, their integration into diverse processes could usher in a new era of productivity and innovation across multiple sectors.

The Future of AI in Laser Welding and Beyond

Looking ahead, the trajectory of AI in laser welding points toward even greater automation, with potential developments including fully automated equation selection and optimization. Such advancements could further reduce human intervention, allowing for real-time adjustments during welding operations. If realized, this could streamline innovation cycles, ensuring that manufacturers keep pace with the accelerating demands of modern industries like electric vehicle production.

The benefits of these future possibilities are manifold, ranging from improved weld quality to significant cost reductions. Enhanced predictive models could minimize material waste and rework, while faster research timelines might bring new products to market more quickly. Industries dependent on precision welding stand to gain immensely, as AI-driven frameworks could ensure consistent, high-quality outputs even under challenging conditions, fostering trust in critical applications.

However, challenges remain, including the current reliance on human oversight and the difficulty of generalizing AI models across varied welding scenarios. While the technology boosts productivity, there is a risk of over-reliance without expert input, potentially leading to suboptimal outcomes. Addressing these hurdles will require ongoing refinement of AI systems and a commitment to integrating domain expertise, ensuring that the positive impacts of enhanced efficiency are not undermined by unforeseen limitations.

Key Takeaways and Call to Action

Reflecting on this trend, it is evident that AI plays a pivotal role in overcoming data scarcity in laser welding, with LLM-powered frameworks offering remarkable efficiency in generating predictive equations. These tools have already demonstrated their practical impact by mitigating defects like humping, ensuring higher quality in critical manufacturing processes. Their ability to transform unstructured data into actionable insights marks a significant leap forward for industrial research methodologies.

The importance of this development in reshaping manufacturing cannot be overstated, as it paves the way for faster, more reliable innovation. The journey of AI integration in this field underscores a powerful synergy between technology and human skill, highlighting a model for future advancements. Industry professionals, researchers, and innovators are encouraged to explore how AI can be harnessed in their own domains, fostering collaboration to unlock new possibilities while maintaining the critical balance of expertise and automation.