Boston Dynamics, a renowned 32-year-old robotics company, has introduced a significant update to its product lineup, marking a new era in robotics technology. Known for the acrobatic movements and dances of its robots, their latest advancement involves launching an all-electric version of their humanoid robot Atlas, replacing the previous hydraulic models that have been in use for 11 years. This shift to electric motors holds considerable implications for cost, design, and performance within the robotics domain.

The Transition from Hydraulics to Electric Motors

Hydraulics: Strength and Load-Bearing Capabilities

Hydraulics, which use fluid and pistons to move machinery, typically offer robust load-bearing and strength capabilities. These systems have been the backbone of Boston Dynamics’ robots for over a decade, providing the necessary power to perform complex and heavy-duty tasks. However, hydraulics come with their own set of challenges, including noise, complexity, and maintenance requirements. Such systems, while powerful, are often cumbersome and require significant upkeep, making them less ideal for widespread commercial use.

The reliance on hydraulics has shaped the design and function of previous Atlas versions, allowing them to execute impressive physical feats. Despite the raw power and versatility of hydraulic systems, their inherent drawbacks cannot be overlooked. Noise pollution, frequent maintenance, and the internal complexity of these systems are all factors that have driven Boston Dynamics to explore alternative solutions. With the all-electric Atlas, the company aims to retain the functional strengths of hydraulics while addressing these key weaknesses.

Electric Motors: Quieter and More Practical

In contrast, electric motors, which rotate and move parts directly through electrical energy, are quieter, lighter, less complex, and often cheaper. This makes electric motors a more practical solution for commercial applications, due to their reduced noise and maintenance requirements. However, electric motors might wear out more quickly and lack the same strength as hydraulic systems, presenting a trade-off between durability and practicality. The simplicity and efficiency of electric motors are compelling benefits that are driving the transition in the robotics industry.

The shift to electric motors also brings about significant design advantages. Electric motors enable a more streamlined and elegant design, reducing the overall weight and complexity of the robot. This not only enhances the robot’s aesthetic appeal but also its functional efficiency. Furthermore, electric motors contribute to a quieter operation, making the new Atlas more suitable for environments where noise reduction is crucial. Reduced maintenance needs translate to lower operational costs, making the robots more accessible and appealing to a broader range of industries.

Implications for Cost, Design, and Performance

The shift from hydraulics to electric motors is filled with considerable implications for cost, design, and performance within the robotics domain. Electric motors offer a more streamlined design, reducing the overall complexity of the robot. This transition also impacts the cost of production, making the robots more affordable and accessible for various industries. The performance of the new electric Atlas robot, as demonstrated in a video by Boston Dynamics, shows impressive capabilities, indicating a promising future for this technology.

By shedding the bulk and intricate mechanisms of hydraulics, the new Atlas can be produced at a fraction of the cost, without compromising on performance. The robot’s enhanced agility and efficiency, coupled with reduced manufacturing and maintenance expenses, position it as a compelling option for diverse applications. Companies looking to integrate advanced robotics into their operations can now do so more economically, promoting greater innovation and automation across sectors.

The Capabilities of the New Electric Atlas

Advanced Movements and Supernatural Characteristics

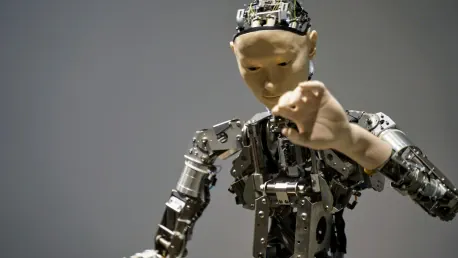

The new electric Atlas robot can stand up and walk confidently, even from a lying flat position. The robot’s movements exhibit characteristics almost supernatural compared to human anatomy, likened to something directed by Sam Raimi, known for his work on the Evil Dead series and the Spider-Man movies. This advanced leap in humanoid robotic technology is designed to not just meet but surpass its predecessors in both strength and the range of motion.

Boston Dynamics has engineered Atlas to tackle complex environments with unprecedented ease. The ability to effortlessly transition from horizontal to vertical stances demonstrates its robust balance and control systems. Beyond basic mobility, the robot’s nuanced articulation and fluid movements suggest a level of finesse previously unseen in humanoid robots. Such capabilities expand the potential applications of Atlas, ranging from disaster response and rescue operations to dynamic interaction with human operators in industrial settings.

Handling Complex Tasks and Heavy Objects

The new electric Atlas includes the ability to handle complex tasks and manipulate heavy, irregular objects using newly developed gripper technologies. This versatility is a clear indicator of Boston Dynamics’ commitment to pushing the boundaries of robotics design. The robot’s ability to perform such tasks efficiently showcases its potential for various industrial applications. By combining advanced motor functions with intuitive control systems, Atlas is equipped to execute precision tasks that demand both strength and dexterity.

In manufacturing and assembly lines, Atlas can undertake roles traditionally reserved for multiple specialized robots, contributing to greater operational efficiency and cost savings. Its gripper technology, capable of adapting to diverse object shapes and weights, exemplifies the flexibility and intelligence infused into its design. This adaptability is crucial in dynamic environments where tasks are not uniform, and rapid adjustments are necessary. As industries increasingly lean towards automation, a robot like Atlas becomes indispensable for its combination of brute force and finesse.

Initial Applications in Automotive Manufacturing

Initially, the new electric Atlas is set to be utilized in automotive manufacturing by Hyundai, Boston Dynamics’ parent company. Hyundai’s automotive manufacturing processes are already heavily roboticized, with significant investments in this field. Boston Dynamics explains that Hyundai, given its pioneering work in next-generation automotive manufacturing capabilities, provides an ideal environment to test and develop new Atlas applications.

Hyundai’s advanced production facilities, equipped with high-tech assembly lines, serve as a fertile ground for implementing Atlas. The robot’s introduction is expected to augment the speed and precision of automobile manufacturing, handling tasks that range from assembling intricate components to managing heavy lifting autonomously. This collaboration will not only streamline Hyundai’s production but also offer valuable insights into refining Atlas for broader industrial use. The symbiosis between manufacturer and robotic innovator is likely to set new benchmarks in the industry, heralding a future where humanoid robots are integral to manufacturing processes.

Boston Dynamics’ Tumultuous Business History

Founding and Early Challenges

Boston Dynamics, despite its cutting-edge technological reputation, has had a tumultuous business history. Founded by MIT professor Marc Raibert and his PhD student Robert Playter, the company initially faced challenges in commercializing its robotics. The journey from a research-focused entity to a commercially viable company has been filled with ups and downs. The initial focus on developing sophisticated robotic systems without a clear commercial path led to financial instability.

However, the groundbreaking nature of their innovations kept them in the spotlight, attracting the interest of major tech players. Despite the commercial challenges, Boston Dynamics remained committed to pushing the envelope of what is possible in robotics. Their determination to pioneer advancements like dynamic balance and mobility in robots ultimately paid off, garnering recognition and support from various investors. The early struggles served as a crucible, shaping the company’s resilience and adaptability in a rapidly evolving technological landscape.

Acquisitions and Ownership Changes

The company was acquired by Google in 2013, sold to Softbank in 2017, and eventually acquired by Hyundai in 2021 for nearly $1 billion. These ownership changes reflect the evolving landscape of the robotics industry and the strategic importance of Boston Dynamics’ technology. Each acquisition brought new opportunities and challenges, shaping the company’s current direction. Google’s acquisition aimed to leverage their robotics expertise within broader AI and machine learning frameworks but ultimately decided to divest.

Softbank’s tenure focused on capitalizing on commercial potential, laying the groundwork for broader market applications. Hyundai’s acquisition marked a strategic alignment of Boston Dynamics’ cutting-edge robotics with a global manufacturing powerhouse, aiming to revolutionize industrial automation. The varying visions of these owners reflected the multifaceted potential of Boston Dynamics’ innovations, from pioneering research to practical, scalable solutions in manufacturing and beyond. Each transition pressed the company to adapt its strategic focus, culminating in a robust framework integrating advanced robotics with commercial viability.

Commercialization of Robotics Products

While the first Atlas robot introduced in 2013 was never commercialized, the Spot robot, launched in 2020, has found applications in many fields, including law enforcement and the military. Boston Dynamics has been cautious about weaponizing its products, focusing instead on practical and beneficial applications. The commercialization of Spot marked a significant milestone for the company, demonstrating its ability to bring advanced robotics to market. Spot’s success underscored the practical value of Boston Dynamics’ robotics, translating complex research into operational efficiencies across various sectors.

Spot’s applications expanded rapidly from routine inspections and surveying in hazardous environments to applications in healthcare during the COVID-19 pandemic, emphasizing its versatility. Spot’s deployment in these fields validated Boston Dynamics’ approach to robotics, illustrating how sophisticated technology can be adapted for real-world problem-solving. The cautious approach to weaponization reflects an ethical stance within the company, prioritizing beneficial uses while navigating the complex landscape of robotics in security and defense.

Increasing Competition in Humanoid Robotics

Major Players in the Market

The timing of the all-electric Atlas comes in a period of increasing competition in humanoid robotics, with significant players like Tesla’s Optimus, the well-funded Figure startup backed by OpenAI, and Amazon’s partner Agility Robotics all vying for a foothold in the market. This competitive landscape drives innovation and pushes companies to continuously improve their technologies. Tesla’s foray into humanoid robots through Optimus represents a significant benchmark, combining high-end AI with mechanical precision to develop versatile household and industrial robots.

Similarly, Figure aims to leverage advanced machine learning to create adaptive robotic systems capable of complex interactions and learning from their environments. Amazon’s collaboration with Agility Robotics is geared towards revolutionizing warehouse operations, aiming for a seamless integration of bots for efficient logistics handling. This heightened competition fosters a rapid pace of innovation, pushing companies to refine their technologies, bring down costs, and expand the practical applications of humanoid robots.

Collaborative Robotics and Market Investments

Boston Dynamics, a prominent robotics company with a 32-year history, has made a notable update to its product lineup, heralding a new chapter in the field of robotics. The company, well-regarded for the agility and dance routines of its robots, has announced the introduction of an all-electric version of its humanoid robot Atlas. This electric model replaces the older hydraulic versions that have been operational for the past 11 years. Transitioning to electric motors is significant as it brings major implications for various aspects like cost efficiency, design flexibility, and overall performance in the robotics industry. This advancement underscores Boston Dynamics’ commitment to innovation and its role in pushing the boundaries of what robots can achieve. The move to electric engines is expected to enhance the robot’s versatility and operational longevity, addressing previous challenges tied to hydraulic systems. This milestone reflects a broader trend in robotics toward more sustainable and efficient technology solutions.