A collaborative research effort has successfully engineered a high-resolution electronic skin built upon a breathable nanomesh substrate, effectively overcoming critical barriers that have previously hindered the long-term viability and comfort of wearable health monitoring technologies. Published in the journal Materials Today, this development introduces a novel manufacturing technique that promises to accelerate the commercialization of comfortable, high-performance electronic skin. The joint team, led by researchers from DGIST, Hanbat National University, and Kyungpook National University, has solved a long-standing paradox in wearable electronics: how to create a device that is both electronically sophisticated and gentle enough for continuous, direct contact with the human body, opening new frontiers for personalized medicine and human-machine interfaces.

The Challenge of Creating Ideal E-Skin

Balancing Performance and Comfort

For any e-skin device to transition from a laboratory curiosity to a practical healthcare tool, it must master a delicate balancing act between two fundamental and often competing requirements. The first is achieving what is known as “conformal contact.” This refers to the device’s ability to adhere intimately and seamlessly to the complex, microscopic topography of human skin, including its countless wrinkles, pores, and fine lines. This incredibly close contact is not merely for stability; it is essential for the accurate and reliable acquisition of subtle biosignals. High-fidelity measurements of electrocardiograms (ECG) for cardiac monitoring, electromyograms (EMG) for muscle activity, or minute changes in skin temperature and hydration all depend on a sensor that moves and flexes as one with the skin. Any air gap or slippage, no matter how small, can introduce noise and corrupt the data, rendering the device ineffective for its primary purpose of sensitive, continuous health tracking. This need for perfect adhesion has historically pushed designers toward using solid, adhesive-backed materials that act like a second, impermeable skin.

The second, equally crucial requirement is maintaining high breathability, a factor directly tied to user comfort and long-term viability. This stands in direct opposition to the traditional materials used to achieve conformal contact. When a conventional e-skin device uses a solid, non-porous substrate, it effectively seals off a patch of skin from the surrounding environment. This barrier prevents the natural process of transpiration, trapping sweat and moisture against the epidermis. Over extended periods of use, which are necessary for meaningful health monitoring, this trapped moisture creates a warm, damp environment that can lead to significant user discomfort, skin irritation, maceration, and inflammation. In more severe cases, it can foster bacterial growth and lead to infections, transforming a tool meant to improve health into a potential liability. This fundamental conflict between high-fidelity sensing and long-term skin health has been a persistent roadblock, severely limiting the practical application and widespread adoption of continuous, wearable e-skin technologies.

The Nanomesh Dilemma

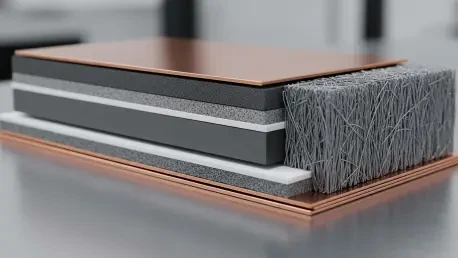

In the quest for a material that could resolve this conflict, nanomesh substrates have emerged as a highly promising candidate for the next generation of e-skin. A nanomesh is not a solid film but a complex, non-woven fabric composed of intertwined polymer nanofibers, creating a web-like structure with countless microscopic pores. This unique architecture is its greatest strength, as it allows for the free passage of air and water vapor, making the material exceptionally breathable. Unlike its solid counterparts, a nanomesh allows the skin underneath to function naturally, enabling sweat to evaporate and heat to dissipate. This property is ideal for maintaining healthy skin conditions even during prolonged and continuous wear, directly addressing the critical issue of user comfort and biocompatibility that has plagued previous e-skin designs. Theoretically, nanomesh offers the perfect foundation: a flexible, lightweight, and breathable scaffold upon which to build sophisticated electronic systems for seamless integration with the human body.

However, the very properties that make nanomesh a desirable substrate have also presented a series of formidable manufacturing challenges that have, until now, stalled its progress. The material’s surface is inherently rough and uneven at the micro-scale due to the tangled, web-like arrangement of its constituent fibers. This topography makes it exceedingly difficult to fabricate the precise, high-resolution electronic patterns—such as conductive traces, electrodes, and sensor arrays—that are required for advanced functionality. Standard microfabrication techniques like photolithography demand a perfectly flat and stable surface to achieve the necessary detail. Furthermore, the polymer-based composition of nanomesh makes it highly vulnerable to the extreme conditions characteristic of conventional electronic manufacturing processes. The high temperatures, harsh chemicals, and plasma etching used in semiconductor foundries can easily cause the delicate nanofibers to melt, deform, or chemically degrade, destroying the substrate’s structural integrity and precluding its use in standard, scalable production lines.

A Novel Manufacturing Solution

The Indirect Transfer Method

The research team’s central innovation lies in a novel and elegant manufacturing method designed specifically to circumvent these seemingly insurmountable structural and thermal limitations. They introduced a new process called “indirect transfer,” ingeniously adapting a proven technology already widely used in the mainstream semiconductor industry for creating flexible electronics. Instead of confronting the challenge of building delicate electronic circuitry directly onto the rough and thermally sensitive nanomesh surface, the team took a completely different approach. They first fabricate the high-resolution electronic components—the sensors, electrodes, and interconnects—on a separate, ideal, and temporary substrate. This carrier substrate is typically a silicon wafer, chosen because it is perfectly flat, smooth, and can easily withstand the high temperatures and chemical treatments of standard fabrication, allowing for the creation of flawless, high-performance circuits using existing tools and techniques.

Once the electronic circuits are fully formed, tested, and confirmed to be functional, they are carefully lifted from this temporary carrier wafer. This is followed by the final, critical step: the functional electronic layer is precisely and gently transferred onto the final nanomesh substrate. This clever, multi-step approach effectively decouples the sensitive nanomesh material from the harsh fabrication environment. The polymer mesh is never exposed to the high temperatures or corrosive chemicals that would otherwise destroy it. This method allows for the best of both worlds: the creation of intricate, high-performance electronics with the precision of semiconductor manufacturing, integrated onto a foundation that is supremely breathable, flexible, and comfortable for long-term wear against human skin. This breakthrough effectively removes the manufacturing bottleneck that had previously prevented the use of advanced nanomesh materials in high-performance wearable devices.

Superior Performance and Durability

The electronic skin produced through this innovative indirect transfer method exhibits a suite of remarkable and superior characteristics that set it far apart from previous attempts. One of the key achievements is the development of ultra-thin nanomesh electrodes that maintain high electrical conductivity at an unprecedented thickness of 20 nanometers or less. This represents a significant leap forward, as existing nanomesh electrodes typically require a thickness of at least 100 nanometers—five times greater—to ensure stable and reliable conductivity. This dramatic reduction in thickness directly contributes to the device’s enhanced flexibility, light weight, and its ability to conform almost perfectly to the skin’s surface. The result is a device so thin and unobtrusive that it is virtually imperceptible to the wearer, a critical factor for ensuring user compliance and comfort during the continuous, 24/7 monitoring scenarios for which it is designed. This ultra-thin profile minimizes mechanical stress on the skin and allows for more natural body movement.

Beyond its impressive thinness and conductivity, the device demonstrated exceptional durability and resilience when subjected to a battery of rigorous tests designed to simulate demanding real-world conditions. It maintained stable electronic performance with minimal signal degradation even when subjected to extreme mechanical deformation, such as being bent repeatedly to a tight radius of curvature between 0.5 to 2.5 millimeters. This proves its suitability for application on highly dynamic and flexible body parts like finger joints, elbows, or knees, where other devices would quickly fail. Furthermore, the electrodes showed robust resistance to a variety of chemicals commonly encountered in daily life, including water, hydrogen peroxide, and acetone, ensuring their integrity and functionality against exposure to sweat, skin lotions, and cleaning agents. Critically, the e-skin also proved to be highly stable under a wide range of physiological conditions, withstanding high temperatures, humidity, and pH fluctuations that mimic the dynamic and often challenging environment of the human skin surface.

A New Era for Wearable Health

This research marked a pivotal advancement toward the realization of truly wearable and comfortable electronic skin for a new generation of medical devices. By ingeniously applying semiconductor transfer technology to a breathable nanomesh platform, the researchers created a device that successfully integrated high-resolution electronic performance with the material properties necessary for long-term skin compatibility. This achievement not only solved a long-standing technical challenge but also represented a significant step forward in the potential commercialization and widespread adoption of breathable electronic skin. The development laid the groundwork for continuous health monitoring systems, advanced diagnostics, and more intuitive human-machine interfaces that could fundamentally change how healthcare is delivered and how humans interact with technology.