The vast digital libraries of computationally designed materials hold the promise of transforming industries from energy to medicine, yet the overwhelming majority of these revolutionary substances exist only as theoretical models on a server. Researchers at the Massachusetts Institute of Technology have developed a novel generative artificial intelligence model named DiffSyn that directly confronts this critical bottleneck in materials science. This innovative tool functions as an expert digital chemist, capable of translating complex material structures into practical, step-by-step synthesis recipes. By effectively providing the missing instructions for creating these advanced materials, DiffSyn is poised to bridge the long-standing gap between theoretical design and real-world laboratory implementation, dramatically accelerating the pace of discovery and innovation. This breakthrough moves the field beyond simply imagining what is possible and provides a concrete roadmap for manufacturing the materials of tomorrow.

Bridging the Gap Between Theory and Reality

The conventional process for creating a new material has long been mired in a laborious cycle of trial and error, heavily dependent on the chemical intuition and accumulated experience of individual scientists. This approach is akin to a master chef attempting to bake an elaborate, multi-layered cake with only a list of desired flavors and textures but no actual recipe. The synthesis of complex materials involves a high-dimensional space where numerous parameters—such as reaction temperatures, processing times, and the precise ratios of precursor chemicals—interact in complex, often unpredictable ways. Even a minor deviation in one of these factors can drastically alter the final properties of the material, rendering it useless for its intended application. This inherent inefficiency and reliance on human guesswork has made the exploration of the millions of promising materials proposed by other AI design tools a prohibitively slow and resource-intensive endeavor, leaving countless potential breakthroughs unrealized.

DiffSyn emerges as a transformative solution, functioning as the expert guide that provides the essential “how-to” for fabricating these complex materials. To achieve this, researchers trained the AI on an immense dataset containing over 23,000 distinct material synthesis recipes meticulously extracted from five decades of scientific literature. The model is built upon a diffusion technique, a sophisticated method also employed by advanced image-generation models like DALL-E. During its training, the model learned to reverse a process of data corruption, effectively de-noising information to restore its original structure. When put into practice, DiffSyn starts with a field of random noise and methodically refines it through a series of steps, ultimately transforming the randomness into a coherent and structured output. In this context, that structured output is a complete and viable synthesis recipe for a scientist’s target material, offering a highly informed starting point that significantly reduces the time and resources spent on experimental guesswork.

A Smarter Approach to Synthesis and Validation

A pivotal innovation that sets DiffSyn apart from previous machine-learning efforts is its adoption of a “one-to-many” mapping paradigm, a concept that more accurately reflects the realities of experimental chemistry. Earlier models often attempted to forge a direct, one-to-one link between a material’s unique structure and a single, definitive synthesis recipe. This represents a fundamental oversimplification, as chemists know that a single material can frequently be created through multiple distinct pathways, each with its own set of conditions and precursors. DiffSyn was explicitly trained to recognize and embrace this complexity, enabling it to map a single target material to a multitude of possible synthesis routes. This sophisticated approach is cited as a primary reason for the model’s state-of-the-art accuracy and superior performance on benchmark tests, as it provides scientists with a range of practical options, allowing them to select the most efficient or feasible path based on available equipment, resources, and expertise.

The model’s practical capabilities were powerfully demonstrated through a compelling proof-of-concept experiment conducted by the MIT team. Researchers tasked DiffSyn with suggesting novel synthesis routes for a new material within the complex class of zeolites. This family of materials was strategically chosen as a test case due to its notoriously difficult synthesis space and long crystallization times, which can often extend for days or even weeks. Any acceleration in identifying a correct recipe in this domain therefore has a high-impact outcome. Following the AI’s guidance, the team successfully synthesized a completely new zeolite material in the laboratory. Subsequent analysis confirmed that the synthesized material not only matched the target but also exhibited improved thermal stability and a promising morphology for advanced catalytic applications, thereby validating the model’s remarkable predictive power. The efficiency gain was staggering; whereas a human scientist might test recipes one by one over weeks or months, DiffSyn was able to sample and propose a thousand different viable synthesis routes in under one minute.

The Future of Automated Material Discovery

Looking forward, the underlying methodology of DiffSyn holds immense potential for expansion into a wide array of other material classes, representing the next frontier in AI-guided synthesis. The researchers are confident that the model’s approach can be successfully adapted to guide the creation of metal-organic frameworks (MOFs), complex inorganic solids, and other valuable materials that are known to have multiple synthesis pathways. The primary challenge in this expansion will be the acquisition and curation of large, high-quality, and well-structured datasets specific to each new material class, as the model’s performance is intrinsically linked to the breadth and depth of the data it learns from. As these datasets become available, the power of this generative AI can be unleashed on an ever-widening range of scientific challenges, promising to accelerate discoveries across numerous fields that rely on the development of novel materials with tailored properties for specific, high-stakes applications.

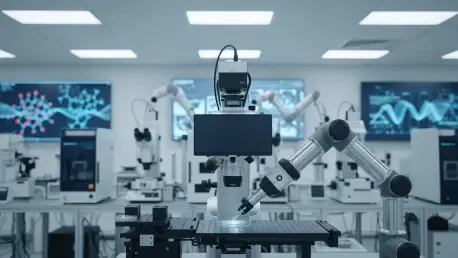

The ultimate vision for this technology involved its seamless integration into fully autonomous systems, which would herald a new era of accelerated materials science. This futuristic concept envisioned intelligent systems where an AI like DiffSyn interfaced directly with robotic laboratory equipment, creating a closed-loop, autonomous feedback cycle for discovery. In this paradigm, the AI would propose a synthesis recipe, a robot would execute the experiment with precision, and the resulting data would be immediately fed back to the model to refine the next set of proposals. Such a system effectively removed the human element from the most time-consuming aspects of experimentation, dramatically accelerating the entire materials design-and-discovery pipeline. This integration represented the critical next step toward a future of on-demand material creation, where scientists could specify desired properties and have a physical sample produced with unprecedented speed and efficiency.